Laser technology has evolved tremendously, especially regarding engraving and marking materials. Precise, effective results are the highlight of UV laser technology. This is owing to a staggering desktop laser marking machine revolution with UV lasers as its focal point. It can now successfully mark or engrave delicate materials without causing any injuries. Whether it’s small industrials or large-scale businesses, all use laser UV marking machines.

Whether you are looking forward to using UV lasers for the first time or you want to upgrade your current infrastructure, this write-up assists you with step-by-step instructions. UV lasers also possess unique functionalities that set them apart from the crowd. Alongside advantages, further in the article, we will discuss the methods and tools that can help step up your business, craft, or marketing goals and assist you in making informed choices.

What is a UV Laser Marking Machine?

The technology functions by “cold marking” the material’s surface without generating heat; this is done using a high-energy UV laser beam. This technology is perfect for fragile plastics, glass, and metals. The precision offered by UV laser marking machines makes them popular in the electronics industry, medical devices, and even pharmaceuticals, because they produce clean and high-contrast marks without harming the material.

How does a UV laser marking machine work?

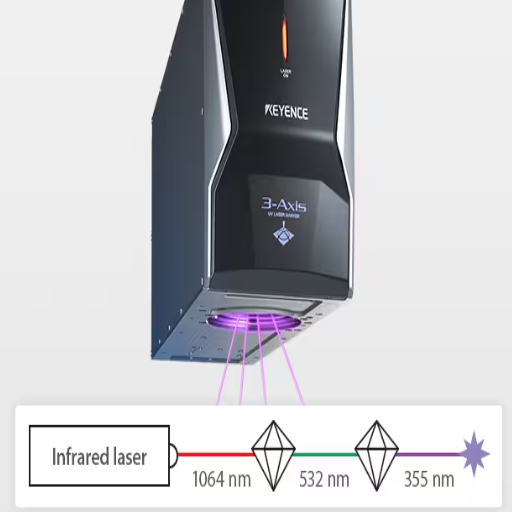

Machines for UV laser marking engrave marks using the process of photochemical reaction. The laser produces a high-energy UV beam with a wavelength of approximately 355 nm. This beam focuses heavily on the material’s surface, concentrating the beam so intensely that the laser interacts with the material at a molecular level. The bonds are broken, but without any thermal impact.

- Laser Beam Generation and Focusing

Like solid-state lasers, advanced laser sources employ UV laser beams. Powerful optical components that focus the beam into excessively small spots, frequently under 20 microns, are integrated into these systems, enabling intricate and detailed markings towards the base of the machine.

- Interaction With Material

The UV laser’s effects on the material change the chemical bonds, creating a mark through photochemical ablation. This more precise technique is useful for processing gentle materials like polymers, glass, and ceramics. This technique poses no threat of overheating and damaging the materials.

- High Precision Scanning System

Machines use galvanometer scanners to direct the beam across the material in a specific manner. This enables marking speed optimal for accuracy alongside an impressive precision achievable in some machines, marking as low as 0.01 mm.

- Marking Results

Regarding QR codes, serial numbers, and logos, UV laser marking machines are the best because they have precise and detailed engravings that are clear, readable, and everlasting.

What materials can be marked with a UV laser?

It’s well known that ultraviolet laser marking machines can operate with many materials due to their precise and low thermal impact. Below is a comprehensive compilation of materials alongside their applications that can be labeled using laser marking machines.

- Plastics—UV lasers can be used to mark several types of plastics, such as polycarbonate, PVC, polypropylene, polyethylene, and ABS. This is due to their short wave length, which results in high contrast and clear markings without destructive deformation. This is extremely popular in the automotive, electronics, and medical device industries for marking serial number stickers, QR code labels, or other regulatory information.

- Glass – Marking UV lasers is perfect for glass surfaces because their low range of heat ensures that there will not be any gaps or cracks refractures. This technology is often seen in production industries for marking logos, measurement markings, or Identification numbers on glass bottles, laboratory equipment, and even touchscreens.

- Metals – UV lasers marking coated or anodized metals is an exception. Compared to fiber lasers, they may not be favored when it comes to thick metal surfaces, but they work exceptionally well with aluminum, steel, and gold plating. Precise and optimal markings will always be achievedUltraviolet lasers are focused to mark medical tools where precision is of utmost importance, such as with zirconia and alumina ceramics. These materials are often used in the medical and aerospace industries as they require detailed engravings while heat-sensitive and require ultra-durable surfaces.

- Food, drinks, and pharmaceutical items are also packaged using non-giving materials such as paper or cardboard, which are marked with barcodes and logos, along with expiration dates stamped or printed on them. All of these things use UV-powered customized marking lasers.

- Softer materials composed of circuitry and electronic silicon are also PCBs, which are Printed Circuit Boards. UV Lasers mark all of these without touching and damaging the marked items. This ensures no shredding or deformation, which allows for very elegant markings to be placed.

What are the benefits of using a UV laser for marking?

UV laser marking is popular in several industries because of its numerous advantages. Here are five of them:

- High Precision and Accuracy

UV lasers are capable of repairing intricate designs or small components. Their short wavelength produces minimal deformation or damage to the material being marked, resulting in clear, sharp markings.

- Versatility Across Materials

Rubbers, metals, glass, ceramics, and even delicate components such as silicon wafers are no match for UV lasers. These lasers cater to nearly all purposes in industries like aerospace, electronics, and medical devices.

- Non-Contact Marking

UV laser marking doesn’t exert any physical stress or damage the subject’s surface. For fragile cushions or other delicate items, suitable marking preserves their structural integrity.

- Durability and Permanency

Lastly UV lasers ensure that the markings do not deteriorate over time. The markings themselves are also incapable of being damaged by contact abrasions, chemicals, and ultraviolet exposure. While also serving the purpose of lasting identification and traceability aid, UV lasers face no task as impractical.

- Sustainable Processes

Because UV lasers do not require chemicals, consumables, or extra processing agents, they are considered eco-friendly. The precision with which items are marked reduces waste, making them sustainable marking solutions.

How to Choose the Right Desktop Laser Marking Machine?

The right desktop laser marking machine needs to fulfill several key factors if you wish to meet your requirements.

- Material Compatibility

It is of utmost importance to ascertain whether a machine can mark your materials, be they metals, plastics, or ceramics. Some lasers, like fiber lasers, are better suited for metal, while UV lasers handle delicate materials better.

- Marking Precision and Speed

Consider the level of precision and speed required for your applications. Machines with high precision are great for detailed marking, while machines with faster speeds offer high-volume production.

- Ease of Use

If the marking machine will be used by several operators, an intuitive interface and comprehensive software should be priorities when selecting a machine.

- Durability and Support

Always choose a reliable brand that offers great customer support. This brand ensures robust maintenance services, warranties, and customer demand support.

You will find a machine that satisfies your operational and budgetary demands by analyzing these factors.

What should you consider when selecting a laser engraver?

- Laser Power and Material Compatibility

Materials are power sensitive. A 20W fiber laser works well for marking metals such as stainless steel and aluminum, while CO? lasers perform better for engraving and cutting wood, acrylic, and leather at 40W and above. Lasers with higher wattage provide deeper cutting and faster engraving but can cost significantly more. Remember that the power of the laser must correspond with your needs.

- Engraving Area and Accuracy

You should be strategizing the area set for engraving. Depending on the size of products you intend to work on, some desktop laser engraving machines have engraving areas as small as 8×8 inches to industrial machines 20×20 inches and beyond. Those delicate and intricate designs demand outstanding precision; thus, look out for machines that offer high DPI (dots per inch) capabilities like 1000 DPI or above.

- Software and User-Friendliness

Pay close attention to the software accompanying the device. Check if the grammar has easy-to-use software that interfaces with Illustrator/CorelDRAW. Advanced models allow for greater user convenience, offering wireless internet access, cloud-based software, or touchscreens. Also, check if the software supports basic file types such as SVG, DXF, and PNG.

- Safety Considerations

Important contemporary safety features on modern laser engravers include shields, ventilation hoods, and stop buttons. CO? lasers yield noxious gases during engraving processes on acrylic and plastic. Hence, an internal or external exhaust system is necessary. Safety regulations are also mandatory from an FDA and CE mark point of view.

- Cost vs Value

Desktop laser engravers start at a low price of around $400-$700, and high-end industrial-grade systems can cost more than $5,000. Evaluate if the price is justified based on the features, quality, and estimated lifespan of the machine. Some of the best-rated brands in 2023 are Glowforge for hobby and small businesses, and later Epilog or Trotec, focusing on industrial applications with enduring performance and extensive support.

- Customization and Flexibility

When choosing a machine for your business, be sure it comes with upgrade options like rotary attachments for engraving or lenses that can be added later. This type of modular design not only allows for growth but also minimizes replacements, saving costs in the long run.

By evaluating all the options available, you can ensure that the laser engraver fulfills all of its technical specifications, safety requirements, and business objectives in a streamlined fashion.

What is the difference between fiber laser and UV laser technology?

| Feature | Fiber Laser | UV Laser |

|---|---|---|

|

Wavelength |

~1064 nm |

355 nm |

|

Processing Method |

Heat-based marking |

Cold marking |

|

Material Suitability |

Metals and some plastics |

Heat-sensitive and delicate materials |

|

Precision |

High, excellent for metals |

Extremely fine details on non-metals |

|

Heat Impact |

Moderate, may deform sensitive materials |

Minimal, protects material integrity |

|

Speed |

Higher for metals |

Slower on tough materials |

|

Applications |

Deep metal engravings, rust removal |

Transparent, colored plastics, glass |

|

Initial Cost |

Moderate |

Higher upfront investment |

|

Maintenance |

Lower, longer lifespan |

Moderate, requires more care |

How does spot size affect marking quality?

Marking with lasers requires precision, focus, and proper setting adjustments. This is attributed to spot size, which is also fundamental in determining the quality of laser engraving and etching. Finer marks tend to require small spot sizes, where detail is crucial, like in logos or micro-text, while broad marks, like large text or simple shapes, are easily done using larger spots.

According to recent studies and industry standards, spot size dictates not only resolution but also energy density. A fine spot size allows stronger energy concentration, ideal for deeper engravings on softer metals or plastics. Modern fiber lasers with a calibrated spot size of 20 to 50 microns enable perfect detail and contrast in engraving industries like aerospace and automotive manufacturing. UV lasers are ideal in cases where glass and certain ceramics require gentle marking due to their smaller spot sizes that go as low as ten to fifteen microns.

Insights from recent developments indicate that a reduction in spot size improves the minimum gap achievable between marks, which is crucial for high-density marking layouts. For example, reducing spot size from 30 to 15 microns increases resolution capability by close to 50%, thereby allowing for more legible fine text. Nevertheless, smaller spot sizes ensure text legibility, though they require careful machine calibration and more precise operation, which increases system costs. To conclude, the balance for optimum resolution requirements lies in the material properties and the desired production speed.

What are the Applications of UV Laser Engraving?

UV laser engraving is an advanced technique used in the electronics and medical fields for marking surgical instruments because of the precision and low material impact it creates. With its ability to develop long-lasting, non-invasive markings, it is quite helpfulfor marking surgical instruments in the medical field. In electronics, parts like circuit boards are also marked using laser-traceable methods while preserving the circuit’s functionality. They are also applicable in the packaging industry for marking things like expiration dates or batch numbers on plastic and glass. Lasers can engrave with great precision on various materials, making them a useful tool in manufacturing products.

Where is UV laser marking used in industrial applications?

Laser marking with a UV laser is generally implemented in industries where precision, speed, and versatility are needed, including electronics, pharmaceuticals, and automotive engineering. One example in the electronics field is the use of lasers for marking PCBs, connectors, silicon wafers, and other delicate parts of electronics. They offer the precision required at the micro level, which UV lasers provide without damaging or overheating the materials.

Another significant example is in the automotive industry, where UV laser marking creates sharp, permanent markings on switches and buttons to the more advanced parts like engines. These markings are imperative for traceability, compliance, and quality assurance. For example, UV laser systems are being used to mark the plastics from which automotive panels are made because unlike the other methods used, UV lasers do not deform the surface.

In addition, the pharmaceutical and medical device sectors also make great use of touch-free engraving with a UV laser for security and regulatory reasons. Noninvasive and impossible to alter markings like serial numbers, barcodes, or even QR codes can easily be engraved on syringes, surgical tools, and vials. With the increase of fake medical products, these markings help authenticate and trace real medical stock.

A recent industry analysis has shown that packaging companies are now adopting UV laser marking systems due to their environmentally safe and solvent-free qualities. Lasers are extensively used in consumer goods during product packaging. Laser marking systems are used to engrave logos, batch numbers, and expiration dates on metallized plastics, glass, and metal containers.

The study suggests that the value of laser marking systems will grow to $4.75 billion by 2027, a steady growth of 6.2% from 2021. This shift showcases the increasing use of UV lasers with other industrial marking technologies.

How can UV laser marking enhance traceability in products?

The significance of UV laser marking in traceability lies in its capability to mark permanently and with high precision a wide array of materials such as metals, plastics, and glass. It often includes markings such as serial numbers, QR codes, barcodes, batch numbers, and logos which facilitate accurate identification during different phases of a product’s life cycle.

Recent industry insights highlighted the importance of accuracy in marking with UV laser systems, especially for sensitive materials in the electronics, medical devices, and aerospace sectors. For example, in the electronics sector, UV laser marking enhances the identification of components, which helps in quality assurance and monitoring of counterfeited products. Also, in the medical field, making permanent markings aids in meeting many regulatory compliances like the FDA’s Unique Device Identification (UDI) requirements for safe patient use.

Statistical data supports the growing focus on traceability as a key factor in innovation for laser marking technology. An industrial report claimed that the industrial lasers market, which comprises UV laser marking systems, is projected to grow by 8.9% of CAGR, reaching $9.3 billion by 2030. This hike demonstrates the rise in demand for solutions fulfilling strict requirements to ensure enhanced traceability in supply chains.

UV laser marking increases traceability since it can be integrated with automation systems and smart manufacturing technologies. This allows data to be collected and monitored in real-time, enhancing transparency and operational efficiency throughout the supply chain. Regulatory scrutiny and customer demand continue to rise, and UV laser marking technology gives industries exceptional control over product identification and traceability.

What are the advantages of high-precision marking in medical devices?

Precision marking is essential in the marking of medical devices due to the rigorous regulations within the medical device’ industry. These are five key benefits for utilizing high-precision marking in medical devices:

- Improved Compliance and Tracking

With the implantation of high-precision marks such as unique device identifiers (UDI), MDs achieve regulatory compliance with the FDA and MDR directives. These marks improve traceability during the entire device lifecycle, which augments patient safety and enhances accountability.

- Resistance and Durability

Medical device laser markings are immune to wear and tear, corrosion, and even the autoclaving and chemical cleaning sterilization processes. With laser markings, vital information regarding the device is intact and remains legible throughout its lifespan.

- Lower Chances of Contamination

Markings are free of debris and contamination, which is vital in the healthcare setting. This is only possible with high-edge smooth and non-invasive markings. Low-edge striae markings are made possible through the use of UV lasers.

- Complex Designs for Customized Products

Micro-sized text, logos, or even serial numbers can be included as a result of high-precision marking with complex geometries or delicate materials, ensuring that accuracy is upheld without damaging the materials.

- Improved Identification and Anti-Counterfeiting Measures

Distinct, high-definition precision markings enable the differentiation of authentic and counterfeit medical devices, aiding in brand preservation and safeguarding patients. These markings enable the manufacturer to validate and authenticate his or her devices.

Tips for Operating a Desktop Laser Marking Machine

- Ensure Proper Setup

The device is to be placed on a clean, stable, well-ventilated surface that is free of obstructions and enables operational safety and performance.

- Understand the Material

The power, frequency, and speed settings must be adjusted according to the material to be marked.

- Calibrate the Focus

The laser must be correctly focused to the marking surface using the machine’s focus adjustment tools for precision.

- Follow Safety Precautions

Proper protective eyewear should always be worn and appropriate guidelines established by the manufacturer must be followed. The workspace must be devoid of any flammable materials.

- Test Before Proceeding

Prior to marking the actual product, optimal marking settings should be confirmed by performing a test mark on a sample piece of the same material.

- Perform Regular Maintenance

To prevent performance issues, the lens and other machine components should be cleaned according to the instructions in the user manual.

What is the significance of the 355nm wavelength in UV lasers?

The 355nm wavelength in UV lasers is significant because its ability to concentrate on Focused areas improves productivity, enabling precise marking, engraving, micromachining, and other processes of interest without any thermal effect on the surrounding materials. In terms of engineering thermoplastics like plastics and glass, this wavelength is crucial as it can be processed precisely and without cleaning as well as with accurate further side effects too.

How does UV laser technology compare to CO2 and fiber lasers?

| Feature | UV Laser | CO2 Laser | Fiber Laser |

|---|---|---|---|

|

Wavelength |

355 nm |

10,600 nm |

1,064 nm |

|

Processing Method |

Cold marking, minimal heat |

Heat-based marking |

Heat-based marking |

|

Material Suitability |

Plastics, glass, heat-sensitive materials |

Wood, rubber, acrylics |

Metals, some plastics |

|

Precision |

High, ultra-fine details |

Moderate, less detail |

High, excellent for metals |

|

Heat Impact |

Minimal, protects delicate materials |

Can scorch surfaces |

Moderate, may deform some plastics |

|

Cutting Ability |

Limited, specific materials |

Excellent for organic materials |

Limited to thin metals |

|

Applications |

Medical, electronics, fine engravings |

Woodwork, packaging, art |

Metal engraving, industrial marking |

|

Maintenance |

Moderate, requires care |

High, frequent servicing |

Lower, highly durable |

|

Cost Range |

$12,000–$25,000 |

$2,000–$20,000 |

$5,000–$160,000 |

What makes UV laser engraving suitable for plastics?

Moreover, the effectiveness of UV laser engraving makes it particularly advantageous for various grades of plastics because of its high versatility, low impact of heat, and shallow grade plastic. By contrast to CO2 or fiber lasers, UV lasers are stronger due to operating at a lower wavelength ~355nm marking of cold marking microscopic or without ample damage changing any coarse. This helps keep warping, discoloration, or degrading the material beyond disfiguration at high levels of precision when using high-heat laser systems.

UV laser wavelengths are the top priority of focus when achieving maximum efficiency because of their high absorption rate in plastics. Their use with polycarbonate, steel, polyethylene, PVC, nd and ABS provided the highest contrast for UV laser markings, with blurring of exceptional detail and precision, making them most optimum for industrial use. Studies proving how by using UV laser marking pace up to 400 characters per second on plastic materials from claim level to средними levels, while ensuring grade surpassing fps further proves the applicability of UV lasers.

Moreover, UV Laser engraving helps maintain compliance for sensitive sectors like medical devices and consumer electronics. It also assists in traceability for the consumer while protecting the integrity of the plastic components by marking them with barcodes, serial numbers, logos, etc. Plastics processing across different industries prefer using UV laser engraving because of the precision, reliability, and compatibility it offers.

Reference Sources

-

This document examines the procedures and equipment associated with laser etching to include applications of UV lasers.

-

Evaluation of Marking Technology for Risk Management in the Biopharmaceutical Supply Chain:

This evaluation study aims to analyze laser markings, including the use of UV lasers, for marking medical commodities such as syringes and vials.

- Top UV Laser Marking Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a desktop UV laser marking machine?

A: A desktop UV laser marking machine is a type of laser marker that utilizes a 355nm UV laser source to mark and engrave a wide range of materials with high-contrast markings. It is designed for precision tasks, including engraving on delicate plastics and curved surfaces.

Q: How does the marking process work with a laser marker?

A: The marking process with a laser marker involves directing a focused beam of UV light onto the material’s surface. This process allows for precise engraving and marking tasks, creating high-contrast markings without the risk of damage or heat stress to the material.

Q: What types of materials can be used with a desktop UV laser marking machine?

A: A desktop UV laser marking machine can mark and engrave various materials, including plastics, metals, glass, and wood. The precision of the 355nm UV laser allows for versatility across various applications.

Q: What is the advantage of using a flying laser in marking tasks?

A: A flying laser system allows for continuous marking during the movement of the material, which increases efficiency and productivity. This setup is particularly beneficial for high-volume production environments requiring multiple marking tasks.

Q: Can the laser marking machine accommodate cylindrical objects?

A: Yes, many desktop UV laser marking machines can mark cylindrical surfaces. Specialized fixtures can hold the objects in position during the marking process, ensuring accurate and consistent results.

Q: How does autofocus work in a laser marking machine?

A: Autofocus in a laser marking machine automatically adjusts the position of the laser head to maintain optimal focus on the material’s surface. This feature enhances the quality of the markings by ensuring the laser beam is always at the correct distance from the material.

Q: What are the maintenance requirements for a desktop UV laser marking machine?

A: Due to their robust design, desktop UV laser marking machines typically require minimal maintenance. Regular cleaning of the laser head and checking of the marking program are essential to ensure optimal performance and longevity, contributing to low maintenance costs.

Q: How can design software be utilized with the laser marking machine?

A: Design software can be used to create and prepare 3D files for marking and engraving tasks. This software allows users to customize their designs, including traceability marks, before sending them to the laser marking machine for execution.

Q: What should I consider when choosing a desktop UV laser marking machine?

A: When choosing a desktop UV laser marking machine, consider factors such as the range of materials you plan to mark, the machine’s power and speed, the type of marking tasks (e.g., flat or cylindrical), and the level of software integration available for your design needs.