Precision, speed, and versatility—these are the hallmarks of modern manufacturing, and fibre laser cutting machines are at the forefront of this technological revolution. Whether you’re in aerospace, automotive, or custom fabrication, these machines are transforming how industries approach material cutting and design. But what makes fibre laser cutting machines so revolutionary? How do they compare to other cutting technologies, and why are they becoming the preferred choice for businesses striving for efficiency and precision? This guide dives deep into the workings, advantages, and applications of fibre laser cutting technology, equipping you with the knowledge to make informed decisions in an evolving industrial landscape.

What is a Fibre Laser Cutting Machine?

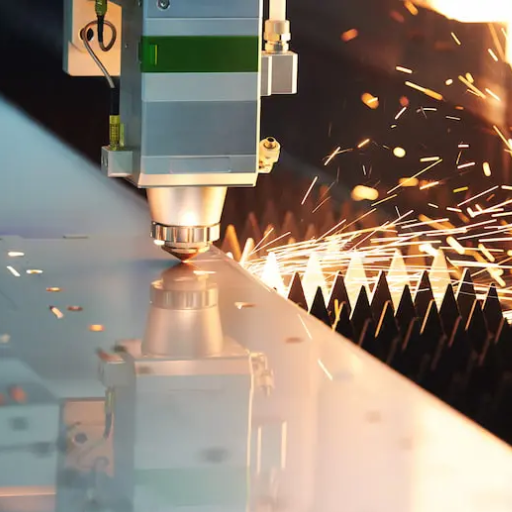

A fibre laser cutting machine is an advanced tool used for cutting and engraving various materials with high precision. It works by using a concentrated beam of laser light, which is generated through optical fibers. This laser beam is powerful enough to cut through metals, plastics, and other materials with exceptional accuracy and speed. Fibre laser cutting machines are highly efficient, require minimal maintenance, and are widely valued for their ability to produce clean, precise cuts. They are often used in industries such as manufacturing, automotive, and aerospace for complex and detailed cutting tasks.

How does a laser cutting machine work?

Laser cutting machines operate by focusing a high-powered laser beam onto a specific area of the material, which is either melted, burned, or vaporized to create a clean cut. The process begins with a laser resonator, where the beam is generated. This beam is then directed through a series of mirrors and a focusing lens, intensifying its energy before it reaches the workpiece. A nozzle emits an assist gas—like oxygen, nitrogen, or compressed air—to expel the molten material and ensure a smooth cutting edge.

Modern laser cutting machines employ advanced CNC (Computer Numerical Control) systems, allowing precise control over the laser’s movements and intensity. These machines can achieve cutting tolerances as fine as ±0.1 mm, making them ideal for applications requiring extreme precision. The cutting speed varies depending on factors such as the material type, thickness, and laser power. For instance, a 4kW fiber laser can cut through 1mm stainless steel at speeds up to 50 meters per minute.

Additionally, newer technologies integrate real-time monitoring tools like cameras and sensors to enhance accuracy and reduce waste. Thermal sensors ensure the consistent temperature of the cutting zone, while advanced software optimizes cutting patterns, minimizing material usage. This combination of precision engineering and innovative technology ensures that laser cutting remains a critical tool for high-demand industries.

What are the components of a fiber laser cutting machine?

A fiber laser cutting machine is a sophisticated system composed of several key components, each playing a vital role in ensuring its precision, speed, and efficiency. Below is an in-depth look at the primary elements:

- Fiber Laser Source

The fiber laser source is the core of the machine, generating high-energy laser beams through the amplification of light in glass fibers doped with rare earth elements like erbium, ytterbium, or thulium. These lasers provide stable and concentrated beam power, typically ranging from 500 watts (W) to over 12 kilowatts (kW), depending on application requirements. High-powered sources enable cutting through various materials, including stainless steel, aluminum, and brass, with thicknesses up to 50mm in some cases.

- Cutting Head

The cutting head is responsible for directing the laser beam precisely onto the material. It incorporates lenses, focusing mirrors, and a protective nozzle. Many modern cutting heads feature auto-focusing technology, enabling seamless adjustment of focal lengths for different materials and thicknesses, thereby improving operational efficiency and cut quality.

- CNC Control System

The Computer Numerical Control (CNC) system serves as the brain of the machine. It interprets design files, typically in formats such as DXF or CAD, and converts them into precise cutting instructions. Advanced CNC systems offer pre-programmed cutting patterns, multi-axis movement, and real-time monitoring capabilities, ensuring accuracy within microns and reducing the risk of cutting errors.

- Power Supply Unit (PSU)

The power supply unit provides the energy necessary to operate the fiber laser source and all auxiliary components. A reliable PSU ensures stable performance for prolonged cutting sessions, particularly in high-production settings. Efficiency in energy consumption is a key feature in state-of-the-art PSUs.

- Cooling System

Efficient thermal management is critical in laser processing. Most fiber laser machines are equipped with water-cooling systems to dissipate heat generated by the laser source and cutting head. These systems utilize industrial chillers to maintain precise operating temperatures, extending the machine’s lifespan and maintaining consistent performance even during demanding applications.

- Bed and Frame Structure

The machine’s bed and frame structure provide the mechanical foundation and stability necessary for accurate cutting. Typically made from high-strength alloy steel or cast iron, these elements are designed to minimize vibrations and maintain rigidity during high-speed operations. Many machines also include interchangeable dual-beds to facilitate continuous production by loading and unloading materials simultaneously.

- Assist Gas Delivery System

An assist gas system is integrated to support the cutting process by removing molten material and improving cutting precision. Commonly used gases include oxygen for carbon steel cutting, nitrogen for non-ferrous metals, and compressed air for cost-effective operation. Automated pressure regulation ensures optimal gas flow based on material type and thickness.

- Optical Transmission System

The optical transmission system delivers the laser beam from the laser source to the cutting head. Unlike traditional CO? lasers that rely on mirrors, fiber lasers use flexible optical fibers for beam transmission. This design minimizes energy loss, enhances beam consistency, and enables compact machine layouts.

- Dust and Smoke Extraction System

During the cutting process, smoke, debris, and fine particulates are generated, which can impede operator safety and machine longevity. Integrated dust and smoke extraction units ensure a clean working environment by removing these byproducts efficiently, often using HEPA filters for superior air quality.

- Software Interface

Modern fiber laser cutting machines come equipped with user-friendly software interfaces. Operators can easily perform tasks such as importing designs, setting cutting parameters, and monitoring system performance. Cutting-edge software also includes AI-powered features like automatic defect detection, predictive maintenance alerts, and production analytics.

By combining these components, fiber laser cutting machines achieve exceptional cutting precision, speed, and versatility, making them indispensable for industries such as automotive, aerospace, electronics, and construction.

What is the difference between fiber and other laser types?

Fiber lasers stand out from other laser types, such as CO2 and crystal lasers, due to their unique design, efficiency, and performance. Unlike CO2 lasers, which use gas as their active medium, fiber lasers utilize a doped optical fiber as the medium, amplifying the light through a fiber optic cable. This solid-state mechanism eliminates the need for delicate mirrors or gases, making fiber lasers far more durable and low-maintenance.

One of the key differences lies in wavelength. Fiber lasers typically operate at a wavelength of around 1 micron, which is much shorter than the 10.6 microns of CO2 lasers. This shorter wavelength allows fiber lasers to focus on much smaller spots, resulting in higher precision and power density for cutting and engraving even the most intricate designs. For example, while CO2 lasers excel at cutting non-metal materials like wood or acrylic, fiber lasers outperform in metal cutting applications, such as stainless steel and aluminum, thanks to their higher absorption efficiency for reflective materials.

Efficiency is another area where fiber lasers surpass alternatives. They offer an electrical efficiency of up to 30-40%, compared to around 10-15% for CO2 lasers. This translates to significantly lower energy costs over time. Additionally, fiber lasers require virtually no optics alignment or consumables, which reduces operational downtime and maintenance expenses.

Finally, fiber lasers boast considerable durability. With their all-fiber construction, they are less vulnerable to environmental factors like dust or vibrations, ensuring a longer lifespan—typically over 100,000 operating hours. Combined with their compact size, fiber lasers provide a practical, reliable, and cost-effective option for a wide range of applications. This blend of precision, durability, and energy efficiency makes them a preferred choice for modern manufacturing and industrial processes.

How Does Fiber Laser Technology Work?

Fiber laser technology operates by using a specially designed optical fiber as the medium to amplify light. High-powered diode lasers provide the initial light source, which is then directed into the optical fiber. Inside the fiber, the light interacts with rare-earth elements (such as ytterbium) embedded in the fiber core, causing an amplification of the light through stimulated emission. The amplified light is then emitted as a highly focused, intense laser beam. This beam is ideal for precision tasks, as it maintains consistent power and quality, making fiber lasers highly effective in cutting, welding, marking, and other industrial applications.

What role do fiber optics play in laser cutting?

Fiber optics play a pivotal role in revolutionizing laser cutting technology, providing an unparalleled combination of efficiency, precision, and versatility. At the core of this innovation is the ability of fiber optics to transmit high-powered laser beams over long distances with minimal energy loss. The optical fibers are designed to guide and focus laser light with exceptional accuracy, ensuring precise cutting even on intricate designs or delicate materials.

One major advantage is the enhanced energy efficiency of fiber lasers, as they convert a higher percentage of input energy into usable laser light compared to traditional CO2 lasers — often exceeding 40% efficiency. This not only reduces energy consumption but also lowers operational costs. Additionally, fiber optics enable consistent beam quality, which is crucial for achieving finer and cleaner cuts with reduced thermal distortion.

Fiber laser systems perform exceptionally well on a wide range of materials, including steel, aluminum, brass, and copper, showing their versatility in industrial applications. For instance, studies and industry reports indicate that fiber lasers can cut thin metals up to three times faster than CO2 lasers, especially in thicknesses under 6mm. Furthermore, these systems require significantly less maintenance, as fiber optic cables are more durable and have no moving parts, translating to less downtime and higher productivity.

These advancements highlight the fundamental role of fiber optics in pushing the boundaries of laser cutting technology, making it an indispensable tool for industries demanding precision and efficiency.

How does the laser beam interact with materials?

The interaction between a laser beam and a material is a complex process influenced by factors such as the type of material, laser power, wavelength, and cutting speed. When the focused laser beam strikes the surface, it delivers a concentrated amount of energy that heats, melts, or vaporizes the material in a precise manner.

For instance, metals such as stainless steel, aluminum, and titanium absorb the high energy of the laser beam efficiently, resulting in localized melting or vaporization. Fiber lasers, known for their shorter wavelengths (typically around 1 micron), are particularly effective for cutting reflective metals like aluminum and copper, as they demonstrate high absorption rates in these materials. Studies show that fiber lasers provide cutting speeds faster by up to 200% compared to CO2 lasers, depending on the material and thickness involved.

Non-metallic materials, such as plastics, ceramics, and polymers, also respond uniquely to laser energy. For example, in cutting or marking plastics, the laser beam creates a clean, precise edge by vaporizing the material without causing excessive heat-affected zones. Advanced laser systems ensure minimal distortion or discoloration, making them ideal for industries requiring tight tolerances and aesthetic quality.

Additionally, the wavelength and intensity of the laser play a significant role. High-power lasers with superior beam quality can cut thicker materials with better edge quality and lower kerf widths. For instance, a 4kW fiber laser can efficiently cut up to 20mm of mild steel with remarkable accuracy.

Beyond cutting, laser beams also enable processes like engraving, welding, and surface treatment. Each application leverages the laser’s ability to control heat input, allowing manufacturers to tailor results to specific material properties. This precision and versatility underline the critical importance of laser technology across various sectors, from automotive to aerospace.

What is the significance of laser power and laser source?

The laser power and laser source are crucial factors that determine the efficiency, quality, and applicability of laser-based processes in industrial settings. Laser power refers to the energy output of the laser over time, often measured in watts. Higher laser power allows for faster cutting speeds, deeper penetration, or higher heat input into the material, making it ideal for heavy-duty applications such as cutting thick metals or welding robust components. For example, industrial lasers with power levels exceeding 10 kW are commonly employed in the automotive industry for high-precision metalwork.

On the other hand, the laser source influences the wavelength, beam quality, and operational efficiency of the laser system. Common laser sources include fiber lasers, CO2 lasers, and diode lasers, each tailored to specific applications. For instance, fiber lasers, with their compact design and high electrical efficiency, dominate the market for precision cutting and engraving tasks. They offer excellent beam quality and are particularly effective for materials like stainless steel and aluminum, with cutting speeds up to 50% faster than traditional CO2 lasers in some cases.

Together, the interplay between laser power and source dictates the adaptability of the technology. For example, high-power fiber lasers outperform in industrial-grade tasks requiring both speed and precision, while low-power diode lasers are more suited for applications like marking or engraving. Selecting the right combination of laser power and source ensures optimal material compatibility, energy efficiency, and desired output, making it an essential consideration for modern manufacturing industries.

What Are the Applications of Fiber Laser Cutting?

Fiber laser cutting is widely used across various industries due to its precision, efficiency, and versatility. Common applications include:

- Automotive Industry: Cutting complex parts, such as body panels and exhaust systems, with high accuracy.

- Electronics: Precision cutting of small, intricate components for devices like circuit boards.

- Aerospace: Processing lightweight yet durable materials, including titanium and aluminum alloys.

- Metal Fabrication: Creating custom parts and designs for construction, machinery, and tools.

- Jewelry and Art: Cutting detailed patterns and shapes from metals to create intricate designs.

These diverse applications highlight why fiber laser cutting has become a critical tool in modern manufacturing.

How is it used in metal fabrication?

Fiber laser cutting plays an essential role in modern metal fabrication, offering a highly efficient and accurate method for processing a variety of metals, including steel, aluminum, brass, and copper. This technology uses a concentrated beam of light to cut, engrave, and shape metal materials with exceptional precision. Capable of achieving cutting speeds of up to 60 meters per minute depending on material thickness and type, fiber laser cutting stands out for its speed and cost-effectiveness.

One significant advantage of fiber lasers in metal fabrication is their ability to handle both thin and thick materials with ease. For instance, they can cut mild steel up to 20 mm thick with unparalleled accuracy, often requiring little to no secondary processing. Additionally, fiber lasers are highly efficient, with energy conversion rates as high as 45%, making them more environmentally friendly compared to traditional CO2 lasers.

Fiber laser systems also support advanced automation, which reduces downtime and increases production throughput. Features like automated loading and unloading, as well as real-time monitoring and control, enable manufacturers to streamline operations and improve output. These capabilities make fiber laser cutting indispensable for industries that demand high-quality, detailed workpieces, from automotive to construction and electronics.

By combining speed, precision, and adaptability, fiber laser cutting has revolutionized metal fabrication, enabling manufacturers to meet modern industrial demands with greater efficiency and superior results.

What range of materials can be cut with fiber lasers?

Fiber lasers are exceptionally versatile, capable of cutting an extensive range of materials with precision and efficiency. Common materials include metals such as stainless steel, carbon steel, aluminum, brass, and copper. Additionally, fiber lasers effectively handle reflective metals, which are traditionally challenging to cut with other laser technologies, thanks to their advanced beam delivery system.

Beyond metals, fiber lasers can also process non-metal materials like plastics, polymers, and certain composites, depending on the system configuration. For instance, plastics such as acrylic, polycarbonate, and ABS can be intricately cut to meet exact specifications.

When it comes to thickness, fiber lasers are highly adaptable. They can cut thin sheets, like stainless steel under 1mm, with extraordinary speed and accuracy, while also being capable of cutting thicker materials. High-powered systems are reported to efficiently slice through stainless steel of up to 30mm thickness. Aluminum, another widely used material, can also be cut with thicknesses exceeding 20mm when adequate power and settings are applied.

The ability of modern fiber lasers to cater to a diverse spectrum of materials makes them indispensable across industries. Their precise control minimizes waste and enhances productivity, ensuring that a wide variety of materials—whether ferrous, non-ferrous, or synthetic—are processed with exceptional quality. This adaptability underscores the pivotal role of fiber lasers in advancing manufacturing capabilities.

What are the benefits over traditional cutting methods?

Fiber lasers provide several key advantages over traditional cutting methods, delivering precision, efficiency, and versatility. One major benefit is their ability to achieve extremely high accuracy, enabling intricate cuts with tolerances as low as ±0.002 inches. This precision minimizes the need for secondary finishing processes, saving time and costs in production.

Another advantage is the remarkable speed at which fiber lasers operate. They can cut through thin metals up to three times faster than conventional methods, such as plasma or mechanical cutting. For instance, a 1mm thick stainless steel sheet can be processed at speeds exceeding 20 meters per minute, dramatically increasing production output.

Fiber lasers also consume less energy compared to traditional methods. With electrical efficiency rates of approximately 25-30%, they significantly reduce operating costs while promoting eco-friendliness. By contrast, older technologies like CO2 lasers often operate at roughly 10-20% efficiency, making fiber lasers the more sustainable choice for modern manufacturers.

The versatility of fiber lasers further distinguishes them. They handle a broad range of materials, including reflective metals like aluminum, brass, and copper, which pose challenges for traditional cutting technologies. Additionally, they offer exceptional durability, with diode lifespans exceeding 100,000 hours, resulting in lower maintenance requirements.

Lastly, fiber lasers generate minimal waste and produce cleaner, smoother edges without introducing significant heat to surrounding areas. This reduces the likelihood of material warping or distortion, ensuring higher-quality end products. These advantages collectively make fiber lasers an essential tool for industries striving for precision, efficiency, and sustainability in their operations.

How to Choose a Fiber Laser?

To choose the right fiber laser, start by assessing your specific application needs. Consider factors such as the type of materials you will be working with, the required cutting or marking depth, and the precision level you need. Evaluate the laser’s power output to ensure it can handle the thickness and composition of the materials efficiently.

Next, prioritize ease of use and compatibility with your existing systems. Look for user-friendly software and controls that allow seamless integration into your workflow. Additionally, check the reliability and durability of the laser by reviewing its lifespan, maintenance requirements, and energy efficiency.

Finally, consider the manufacturer’s reputation and support services. Opt for a supplier known for quality products, excellent customer service, and technical support. This ensures you have reliable assistance if needed and guarantees a better overall experience.

What factors affect cutting speed and precision?

Several factors significantly influence cutting speed and precision in industrial laser cutting processes. First, the type and thickness of the material play a critical role. Thin materials like aluminum or stainless steel allow for faster cutting speeds, whereas thicker sections require slower speeds to maintain accuracy and avoid irregular edges. For example, a 1mm sheet of stainless steel can often be cut at speeds exceeding 20 meters per minute, while a 10mm sheet may require considerably slower speeds around 1-2 meters per minute for precision.

Additionally, laser power and wavelength are key determining factors. Higher power lasers, such as those with 4,000 watts or more, can achieve faster cutting speeds and are better suited for cutting thicker materials. The laser’s wavelength also impacts how effectively energy is absorbed by the material, which directly affects precision. CO2 lasers, for instance, are commonly used for high-precision jobs requiring smooth edges.

The nozzle design and assist gas type also influence outcomes. Proper nozzle alignment ensures the laser beam remains centered, while the assist gas—whether oxygen, nitrogen, or compressed air—removes molten material efficiently. Oxygen can increase cutting speeds for thick materials, while nitrogen is ideal for clean, oxidation-free edges.

Lastly, machine stability and calibration are fundamental. Vibrations or poorly calibrated machinery can lead to irregular cuts and reduced precision. A well-maintained cutting system, paired with state-of-the-art motion controls, can ensure tolerances as tight as ±0.1mm are consistently achieved. By understanding and optimizing these factors, manufacturers can balance speed and precision to meet production demands without compromising quality.

How to determine the right laser power for your needs?

Determining the right laser power for my needs starts with understanding the material I’m working with and the desired outcome. For thicker or denser materials, higher laser power is usually necessary to achieve clean and efficient cuts, while lower power works well for delicate engraving or thinner materials. I also consider the balance between speed and precision—higher power allows for faster processes but may compromise fine details if not carefully controlled. Testing on sample materials is a practical step to fine-tune the settings and ensure optimal results for the specific application.

What are the key considerations for laser cutting technology?

When utilizing laser cutting technology, several critical factors must be considered to achieve optimal performance, precision, and efficiency. Below is a comprehensive list of these considerations:

- Material Type and Thickness

Different materials respond uniquely to laser cutting. Metals like steel and aluminum may require higher power settings, while materials like acrylic or wood typically cut well at lower settings. Material thickness also directly impacts the required power and cutting speed. For example, a 100W laser cutter can effectively cut through metals up to 1/8 inch, but thicker materials may demand more powerful equipment.

- Laser Power and Wavelength

The laser power determines the energy output significant for the cutting or engraving process. Higher-watt lasers (e.g., 150W and above) are better for cutting thicker or harder materials, while lower-watt lasers (e.g., 30W-60W) are suitable for precision engraving. Wavelengths such as CO2 lasers (10.6 μm) or fiber lasers (1.06 μm) also affect compatibility with specific material types.

- Cutting Speed and Feed Rate

Balancing speed and feed rate is essential for maintaining a clean cut. Higher cutting speeds may lead to reduced precision or incomplete cuts, while slower speeds improve detail and edge quality. For example, cutting 1/4-inch plywood might require a slower speed than cutting 1/8-inch of the same material.

- Focus and Beam Alignment

Properly aligning the laser beam and focusing it on the material surface is critical. A misaligned beam can result in inconsistent cutting depths and poor-quality edges. Regular alignment checks and maintenance are essential to avoid defects.

- Gas Assistance and Type

Using assist gases such as oxygen, nitrogen, or compressed air can greatly enhance cutting quality. Oxygen is often used for cutting metals as it supports oxidation, increasing cutting speed. Nitrogen, on the other hand, creates cleaner, oxide-free cuts, commonly preferred for stainless steel applications.

- Ventilation and Safety

Efficient fume extraction systems ensure the safe removal of smoke, fumes, and particulate matter generated during processing. Adequate ventilation is necessary to maintain a safe workspace and prevent harmful exposure to toxic substances.

- Control Software and Automation

Laser cutters rely heavily on control software to manage cutting paths, speeds, and power settings. Advanced software can optimize designs, reduce waste, and improve efficiency. Automation technologies, such as CNC controls, streamline workflows and offer enhanced precision.

- Quality of Optics and Maintenance

The quality of optical components, such as mirrors and lenses, directly impacts the machine’s performance. Regular cleaning, inspection, and timely replacement of these components are fundamental to maintaining consistent results.

- Budget and Operational Costs

Evaluating the overall cost of the equipment, including initial investment, energy consumption, maintenance, and auxiliary gas usage, is essential. For instance, fiber lasers, while more costly upfront, often have lower long-term maintenance costs compared to CO2 lasers.

- Precision and Repeatability

High precision and repeatability are crucial for producing accurate parts, especially in industries like aerospace and medical manufacturing. Machines with precise motion control systems and sturdy mechanical structures help ensure consistent results across multiple production cycles.

- Cooling System

Proper cooling mechanisms, such as water chillers, help prevent overheating of the laser source and maintain stable operation. An ineffective cooling system can reduce the lifespan of the equipment and affect cutting performance.

By carefully addressing these factors, users can unlock the full potential of laser cutting technology, ensuring effective performance and outstanding product quality.

How Do Fiber Lasers Work in Industrial Settings?

Fiber lasers operate by using optical fibers doped with rare-earth elements like ytterbium to amplify light. The laser beam is generated and channeled through the fiber, allowing it to deliver high precision and energy efficiency. These machines are particularly effective in industrial settings due to their robust design, low maintenance needs, and ability to handle both small and heavy-duty tasks. They excel at cutting, welding, and engraving a variety of materials, including metals, plastics, and composites, providing consistent, high-quality results. Fiber lasers are also favored for their compact design and energy savings compared to traditional CO2 lasers, making them a go-to solution for modern manufacturing processes.

What role does the cutting head play?

The cutting head is a critical component in a fiber laser system, playing a decisive role in ensuring precision and efficiency during the cutting process. It houses the optical lenses and nozzles that focus the laser beam onto the workpiece, concentrating the intense energy to achieve clean and accurate cuts. Advanced cutting heads are equipped with features like capacitive height sensors to maintain an optimal distance between the nozzle and the material surface, which is essential for consistent cutting quality.

Modern cutting heads can achieve incredible precision, with cutting tolerances as low as ±0.1 mm, making them indispensable for industries where accuracy is paramount, such as aerospace and automotive manufacturing. Additionally, new-generation cutting heads are designed to handle higher power outputs, often exceeding 10 kW, enabling faster cutting speeds and the ability to process thicker materials. For instance, a well-optimized system can cut stainless steel up to 30 mm thick with remarkable efficiency.

These innovations minimize downtime by incorporating cooling mechanisms and automated cleaning features to reduce debris buildup on optics and nozzles. Through these advancements, the cutting head ensures productivity, durability, and the utmost precision in laser-based manufacturing processes.

How do laser machines maintain accuracy over time?

Laser machines maintain accuracy over time through a combination of advanced technology, meticulous design, and consistent maintenance practices. Key advancements include the integration of real-time monitoring systems, which track beam alignment and output power to ensure the laser consistently delivers precise energy levels. High-resolution encoders and motion control systems enhance positional accuracy, reducing deviations during cutting or engraving tasks.

Additionally, innovative cooling systems play a crucial role by maintaining optimal operating temperatures, which prevent thermal deformation in critical components. Some modern laser machines are equipped with auto-calibration capabilities, allowing them to automatically adjust settings to compensate for wear and environmental changes. Data from recent studies suggests that regular calibration can extend machine accuracy by up to 20%, significantly improving long-term performance.

Maintenance routines also contribute to sustained precision. Routine cleaning of optics, nozzles, and filters ensures that debris does not hinder performance, while software updates provide the latest algorithms for improved functionality. By employing these measures, laser machines can maintain exceptional accuracy across years of intensive use, even in demanding manufacturing environments.

What is the impact of fiber laser systems on production efficiency?

Fiber laser systems have revolutionized production efficiency by offering unparalleled speed, precision, and versatility in various industrial applications. These systems utilize optical fibers doped with rare-earth elements, resulting in compact, energy-efficient, and low-maintenance solutions. Studies indicate that fiber lasers can achieve cutting speeds up to three times faster than CO2 lasers when working with thin metal sheets, significantly reducing production time. Additionally, their high electrical efficiency, averaging around 30-40%, minimizes energy consumption compared to traditional laser systems, which often operate at lower efficiency rates.

This advanced technology also enhances material utilization and waste reduction, as the precision of fiber lasers decreases errors and ensures cleaner cuts. The ability to process a wide range of materials, from metals like aluminum and stainless steel to non-metals such as glass and plastics, supports versatile manufacturing needs. More impressively, fiber laser systems offer a typical lifespan exceeding 50,000 operating hours with minimal maintenance, ensuring consistent productivity and reducing downtime. This robust performance makes fiber lasers a dynamic choice for industries aiming to optimize efficiency, cut costs, and increase production output.

Reference Sources

-

Fiber Laser Cutting of Alumina Substrates for Electronic Applications1:

- Key Findings: This study highlights the superior quality of digitally modulated fibre laser cutting for alumina ceramics. It demonstrates that the strength reduction in materials is primarily due to geometry rather than the laser cutting process itself. The research also suggests that displacing fragile parts of inner contours to areas with less mechanical load can enhance material strength.

- Methodology: The study used a 500W single-mode fibre laser to cut various geometries into alumina substrates. Mechanical strength was tested using a 3-point bending test, and results were compared with finite element simulations.

-

An Overview Study on Laser Technology in Manufacturing2:

- Key Findings: This paper provides a broad overview of laser technologies, including fibre lasers, emphasizing their precision and efficiency in cutting and engraving applications. It compares fibre lasers with traditional methods, highlighting their advantages in accuracy and reduced material damage.

- Methodology: The study reviews existing literature and case studies to analyze the applications and benefits of laser technologies in manufacturing.

-

Laser Drilling of Flexible Printed Circuit Boards Using Pulsed Ytterbium Fiber Laser3:

- Key Findings: The research focuses on the use of pulsed Ytterbium fibre lasers for drilling multi-layer flexible printed circuit boards (FPCBs). It establishes optimal parameters for achieving high-quality holes with minimal thermal damage.

- Methodology: A laser drilling system with a pulsed Ytterbium fibre laser was used to perform hole cutting on FPCBs. The study analyzed the effects of various parameters, such as pulse frequency and duty cycle, on the quality of the drilled holes.

- Top CNC Fiber Laser Cutting Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is a fiber laser cutter and how does it differ from a CO2 laser cutter?

A: A fiber laser cutter is a type of laser cutting machine that uses a solid-state laser, which is generated using a doped fiber as the laser medium. This differs from a CO2 laser cutter, which uses a gas mixture to produce the laser beam. Fiber lasers are generally more efficient and effective for cutting metals and other reflective materials.

Q: What materials can a fiber laser cutter process?

A: Fiber laser cutters can cut various materials, including metals like sheet metal, stainless steel, aluminum, brass, and copper. They are especially effective for cutting reflective materials, which can be challenging for other types of laser cutting machines.

Q: How do fiber laser cutting machines compare to other types of laser cutting machines?

A: Fiber laser cutting machines are part of the solid-state laser family and are generally more energy-efficient, have lower maintenance costs, and offer higher cutting speeds compared to CO2 lasers. They are also superior for cutting metals and reflective materials but may not be as effective for non-metal materials like wood or acrylic.

Q: What are the advantages of using a fiber laser cutter for industrial applications?

A: The advantages of using a fiber laser cutter include its high precision, ability to cut complex shapes, faster cutting speeds, lower operating costs, and minimal maintenance. These machines are ideal for industrial applications that require cutting services for metal cutting and laser marking.

Q: How does the power of the laser affect the cutting capabilities of a fiber laser cutter?

A: The power of the laser directly influences the machine’s cutting capabilities, including the thickness and type of material being cut. A more powerful laser can cut thicker materials and improve the speed and quality of the cut. Fiber lasers generally offer high power and precision, making them suitable for a wide range of cutting applications.

Q: Can a fiber laser cutter be used for laser engraving and laser marking?

A: Yes, fiber laser cutters are versatile machines that can be used for laser engraving and laser marking in addition to cutting. They provide high precision and can create detailed designs and markings on various materials, including metals and plastics.

Q: What factors should be considered when choosing a fiber laser cutting machine?

A: When choosing a fiber laser cutting machine, consider factors such as the power of the laser, the types of materials you plan to cut, the machine’s cutting speed, maintenance requirements, and the specific industrial applications you need it for. It’s also important to evaluate the cost and availability of cutting services and support.

Q: How do CO2 and fiber lasers work differently for laser cutting?

A: CO2 lasers work by exciting a gas mixture in a laser cavity to produce a continuous wave laser beam, while fiber lasers use a laser diode to generate a beam that is amplified through a doped fiber optic cable. This fundamental difference allows fiber lasers to be more efficient and effective, particularly for metal cutting.

Q: What are the typical uses of fiber laser cutting technology?

A: Fiber laser cutting technology is typically used for metal cutting, laser marking, laser welding, and cutting various reflective materials. It is widely used in industries such as automotive, aerospace, electronics, and manufacturing for its precision and efficiency.