Routine Checks & Servicing: Workspaces, along with lenses and mirrors, should be cleaned daily to block any accumulation od objects. Also, coolant levels of both revolving water and anti-freez liquid must be maintained accordingly.

Scheduled Maintenance: Set tasks for cleaning, lubrication, and inspections on a routine basis (daily, weekly, and monthly) to maximize equipment lifespan as well as guarantee its reliable operations.

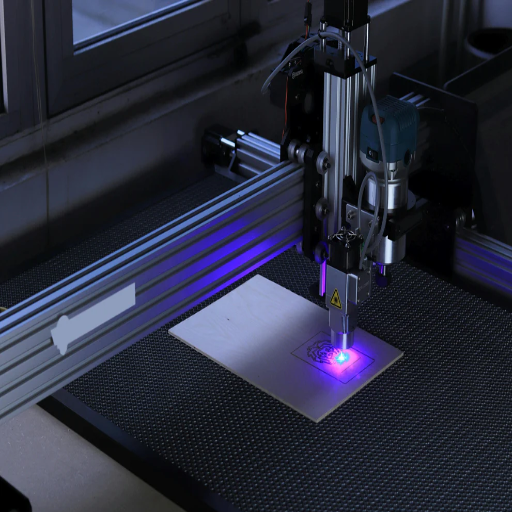

Calibration & Focus Check: Timely execution of testing procedures on laser focus and alignment must be done alongside the marking quality to guarantee exceptional standards on the marks made.

Program Enhancements & Updates: Carry out updates on software and sufficiently train employees on its usage to raise service rates, lower workload, and errors.

Custom Parameters: Set the laser power, speed, and frequency depending on the material marked whether it be wood, glass or metal for the best possible outcomes.